New RevoPortioner Drum Washer: the industry’s lowest water usage

Sustainable cleaning of forming drums

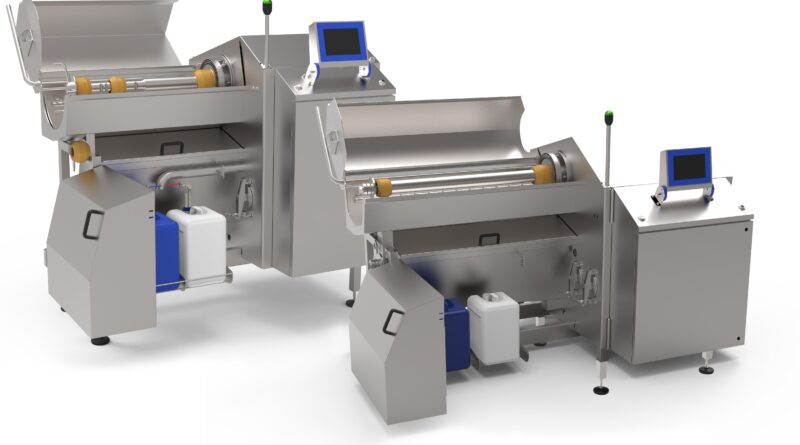

Washing the RevoPortioner drums is vital. Drum clogging must be avoided, as it can prevent the proper release of products in the next forming round. The new RevoPortioner Drum Washer concept gives solid cleaning results while significantly reducing water and energy consumption, establishing itself as a sustainable and profitable solution.

At Marel’s research and development department, engineers are always on the lookout for clever advanced solutions aligned with the company’s sustainability goals. Prioritizing the reduction of water and energy usage, it will come as no surprise that the latest version of the RevoPortioner Drum Washer is a product of our sustainability project.

Compared to the previous washing process, there are proven water and energy savings without, however, compromising cleaning performance. Up to 69% less water and up to 53% less energy can be achieved, with the same clean result over and over again. The bottom line is that it translates into the lowest water usage in drum washing technology.

Software

The RevoPortioner Drum Washer has the latest software implemented to achieve these savings. The new software version is even more intelligent than before and ensures a high-tech management of the completely automated washing program. The secret lies in the smarter use of water in the washing unit, while achieving the same cleaning results.

As before, the drum, which can weigh from 200 up to 500 kilos, is hoisted out of the RevoPortioner using a special cart and placed into the drum washing unit. The addition of the dosage of disinfectant, detergent and water is fully automated. Spanning the entire width of the drum, the cleaning program effectively covers all corners and edges of the molds, ensuring perfect release of the formed products in the next processing round.

HMI screen

The RevoPortioner Drum Washer is equipped with a new user-friendly HMI screen, enabling easy set-up of the washing program. This is where energy and water consumption are controlled. With the new software, processors can access detailed information on the system’s touchscreen, including the real-time progress of the washing process.